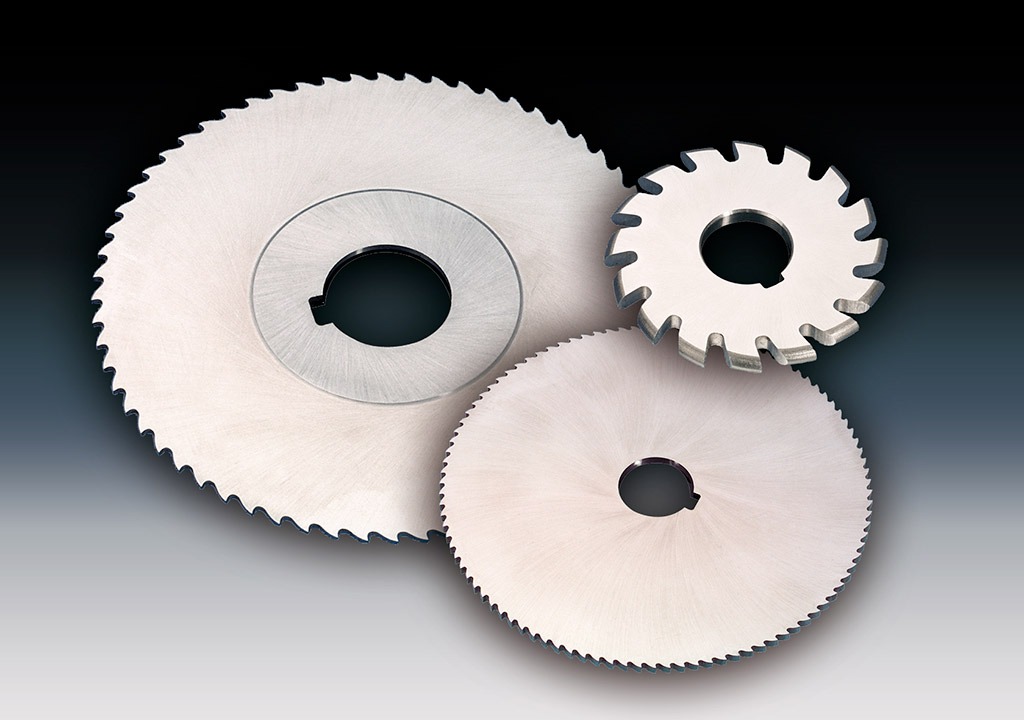

HSS / HSS-E circular saw blades

Leading French manufacturer of high speed circular saw blades

As a circular saw blades manufacturer with decades of experience and a constant commitment to innovation, Caleyron Industries has the skills and technologies to craft a whole range of circular saw blades for several types of industrial cutting tools. Our range covers carbide circular saw blades, tungsten tipped (TCT) saw blades and more speciliazed cutting blades for precision cutting jobs.

Each saw blade is made of high-speed steel HSS or HSS-E according to DIN 1837 and DIN 1838.

The heat treatment is adapted to each grade according to a well-established procedure, which gives the saw blade optimum hardness.

Each HSS or HSS-E saw cutter model can be supplied with STEAM steam treatment which prevents sticking and improves lubrication.

Circular saw blades range

These HSS / HSS-E circular slitting saw blades are manufactured in high speed steel HSS-M2 and HSS-E according to DIN 1837 and DIN 1838. The heat treatment is determined for each grade with a well-defined process assuring an optimal hardness to our tools.

Our circular saws can be supplied with a vaporisation that suits all types of steel, reducing friction and swarf adhesion.

The range includes blade diameters from 20 mm to 600 mm, and thickness 0.2 mm to 6mm

| Material | Grade | Dimensions |

|---|---|---|

| HSS M2 | 1.3343 | 20 to 600 mm |

| HSS-E M35 | 1.3243 | 20 to 600 mm |

| HSS-E M42 | 1.3247 | 20 to 315 mm |

The quality of Caleyron's circular saw blades

Various surface coatings are proposed such as titanium nitride, chromium nitride, etc.

In all cases, these coatings improve the life of saw cutters.

Circular saw blades manufacturer for more than 80 years, we put our know-how and our experience at the service of quality. From the choice of the raw material used to manufacture HSS or HSS-E circular saw blades, to the production process, everything is optimized and controlled. Each manufacturing stage is subject to quality control. Thus, we can offer you models of high quality of circular saw blades. Would you like more information about the HSS cutter or the HSS-E cutter? Do not hesitate to contact our technicians for any information about our products and the company Caleyron.

Applications and usage

| Material | Material to be cut |

|---|---|

| HSS M2 | construction steel, machining steel, bronze, copper, brass, aluminium, cast iron |

| HSS-E M35 | stainless steel, hardened steel, cast iron |

| HSS-E M42 | acier de construction, construction steel, machining steel, stainless steel, titanium alloys, hardened steel, bronze, brass, copper, aluminium |

Special Coatings

Caleyron’s high quality cutting blades are all coated with a special chemical layer that improves according to the hardness and precision level suited for the materials to be cut. Different coatings are proposed such as titanium nitride and chrome nitride coated hardness, cutting capabilities and life expectancy of our products.

In all the cases, these coatings improve the tool’s lifetime.

| Coating | Hardness | Thickness | Color | |

|---|---|---|---|---|

| Chrome nitride | CrN | 1750 HV | 4 | silver |

| Titanium nitride | TiN | 2300 HV | 4 | gold |

| Titanium carbon nitride | TiCn | 3000 HV | 4 | blue-grey |

| Titanium aluminium nitride | TiAIN | 3000 HV | 5 | purple-grey |

| Aluminium chrome nitride | AlCrN | 3200 HV | 3 | blue-grey |