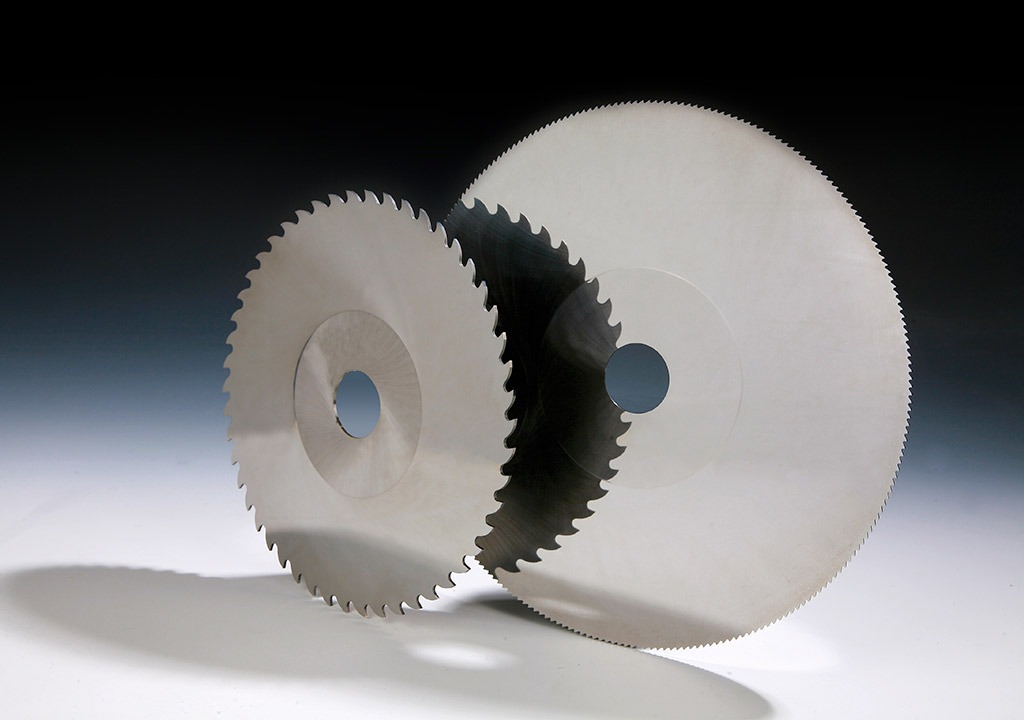

Solid carbide circular saw blades

French manufacturer of solid carbide circular saw blades

Similar to DIN 1837 and DIN 1838. These up-market high quality circular saw blades are employed to cut trough materials or increase tool life in the case of softer materials.

These circular blades are machined with a mirror finish and proper cutting surfaces so close tolerances can be obtained.

Moreover, solid carbide circular saw blades allow higher cutting speeds and feed rates as well a high output. Their lifetime is significantly increased.

We have a wide carbide grade range for each application.

We produce solid carbide saw blades from diameter 20mm to 300 mm and from thickness 0.2 mm to 6 mm.

Solid carbide circular saw blades quality

Since our creation, we have been focusing on the quality of our products, whether for solid carbide circular saw blades or any other tool. During manufacture, at each new stage, saw cutters are inspected. Thus we can assure you a tool of great precision.

| Material | Grade | Dimensions |

|---|---|---|

| Carbide | K10 | 20 à 300 mm |

Carbide circular saw blades applications and usage

With more than 80 years of experience in the design of cutting tools for industries, CALEYRON INDUSTRIES meets the highest demands of the advanced sectors. Our offer includes the manufacture of solid carbide saw blades, in strict compliance with the standards in force.

High-performance and durable cutting tools

We put our know-how at the service of the industrialists who wish to optimize the efficiency and the profitability of their chain of production. The solid carbide saw blade complies with DIN 1837 and DIN 1838. It offers a highly precise result thanks to controlled sharpening and coatings that improve its durability and resistance.

Applications of the carbide circular saw blades

Essential for many machining operations, the solid carbide saw blade cuts all ferrous steels and most non-ferrous metals, such as titanium, stainless steel, bronze, aluminum and copper. Ideal for meeting the challenges of the metallurgical, aeronautical or automotive industries, it also has other areas of application. The carbide saw blade allows high cutting conditions. Thanks to the definition of cutting parameters adapted to your needs, our team is able to design carbide cutters in perfect adequacy with each business challenge. Thanks to our technical team, we are able to design the tool you need.

Special Coatings

| Coating | Hardness | Thickness | Color | |

|---|---|---|---|---|

| Chrome nitride | CrN | 1750 HV | 4 | silver |

| Titanium nitride | TiN | 2300 HV | 4 | gold |

| Titanium carbon nitride | TiCn | 3000 HV | 4 | blue-grey |

| Titanium aluminium nitride | TiAIN | 3000 HV | 5 | purple-grey |

| Aluminium chrome nitride | AlCrN | 3200 HV | 3 | blue-grey |