Cutting tool coatings: choosing the right one for your needs

Publié le 27 May 2025

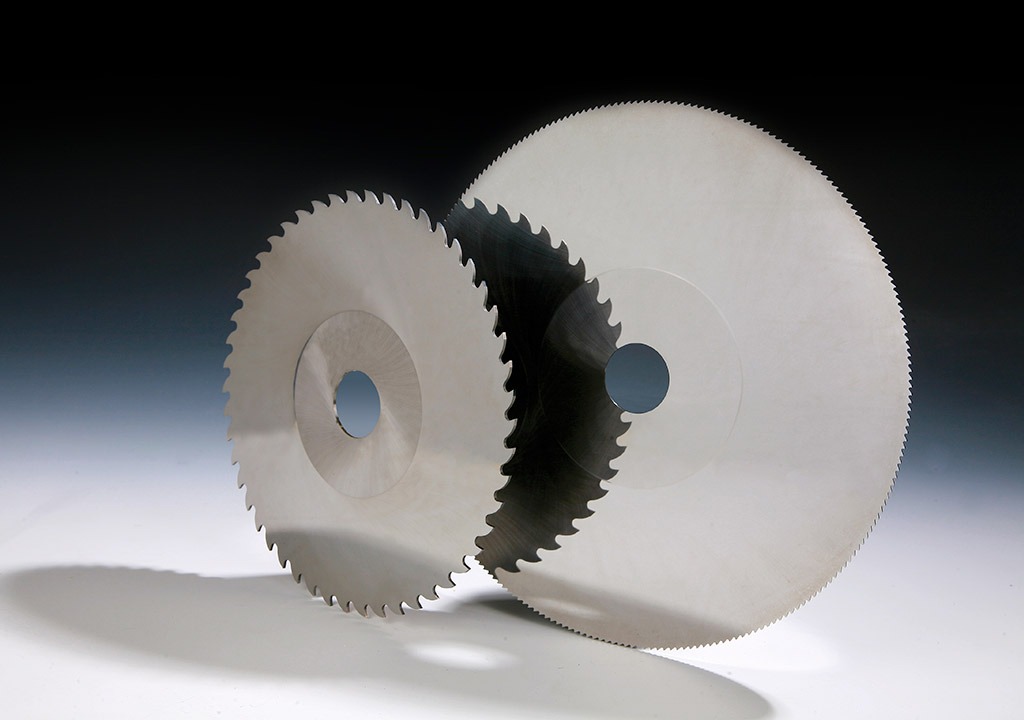

For over 90 years, Caleyron Industries has been designing and manufacturing technical cutting tools for machining professionals: saw-cutters, circular blades, circular knives, 3-cut milling cutters, isosceles milling cutters, conical milling cutters, helical milling cutters... These tools, available in HSS high-speed steel or solid carbide, are offered with a wide range of technical coatings to meet the requirements of every application.

But which cutting tool coating is best suited to your needs? This guide provides concrete answers, depending on the material to be machined and the cutting conditions.

Why is a coating essential?

Cutting tools are subject to very high mechanical, thermal and chemical stress: friction, heating, abrasion, oxidation... A suitable surface treatment enables :

- increase toollife,

- improve cutting quality (surface finish, precision),

- to work at higher speeds,

- reduce or eliminate lubrication in certain cases.

The benefits are tangible: fewer machine stoppages, less scrap, greater repeatability, improved productivity.

How to choose the right coating?

The choice of coating depends on a number of combined parameters:

- the material to be machined (steel, stainless steel, aluminium, cast iron, titanium, etc.)

- type of machining (cutting, trimming, finishing, material flow)

- cutting conditions (dry, lubricated, speed, temperature)

It's not just an aesthetic or marketing criterion, but a strategic technical choice.

Coatings for steel machining

Steel is the most common material, but also the most varied (soft, hard, pretreated, low-alloy, etc.). For standard applications, TiN (titanium nitride) remains a classic: economical, versatile and wear-resistant.

For demanding conditions (hard steels, dry cutting, high temperatures), choose TiAlN (titanium aluminum nitride) for its resistance to oxidation. For intensive applications, AlTiSiN offers exceptional thermal resistance (>1000°C) and superior wear resistance, even without polishing.

HSS saw-cutters used on abrasive steels will gain in efficiency with an AlCrN coating (very hard, low thermal conductivity, excellent against thermal shock).

Cast iron machining: high abrasion

Grey or nodular cast iron is highly abrasive. It quickly wears away edges if the tool is not well protected. Two high-performance options:

- TiAlN: heat resistance and chemical wear resistance,

- AlCrN: resistance to abrasion and material sticking.

For complex or high-performance cycles, opt for AlTiSiN.

Stainless steel machining: heat and bonding

Stainless steel is difficult to cut: it sticks, heats up quickly and wears away edges.

Machining non-ferrous metals: avoiding bonding

Aluminum, copper, brass or bronze are subject to bonding (partial melting on contact with the tool). For this purpose :

- The ta-C (amorphous carbon) coating is ideal: smooth, hard, non-stick, it maintains a sharp edge and prevents burrs,

- CrN (chromium nitride) is an alternative for soft metals such as copper or brass (good chemical resistance).

Machining titanium and special alloys

Titanium is highly abrasive, not very conductive and very adhesive. For lubricated cutting,

A strategic choice for performance

Choosing the right cutting tool coating is essential for :

- extend the life of your tools,

- ensure better production quality,

- reduce machine downtime and production costs.

Chez Caleyron Industries, nous maîtrisons l’ensemble de la chaîne : fabrication de fraises-scies sur-mesure, revêtements techniques, taillage et réaffûtage. Nos experts vous accompagnent pour adapter chaque outil aux conditions de coupe de votre production. Nous vous accompagnons avec un large choix de revêtements PVD et traitements de surface haute performance adaptés à vos applications industrielles les plus exigeantes.

Need advice? Contact our team to define the most effective solution.