How do you find the right circular saw blade for your application?

Publié le 28 October 2025

Do you have a cutting problem, irregular quality or a tool that wears out too quickly?

Are you experiencing cutting difficulties, uneven quality or rapid blade wear?

At Caleyron Industries, we know that no two situations are the same. Every machine, every material and every production process has its own specificities. That's why we offer our customers personalized technical support, based on listening, analysis and real-life testing of our tools.

Our aim: to help you find the best blade for your application, optimize your cutting parameters and sustainably improve the quality and productivity of your operations.

Our method: personalized support from A to Z

Understanding your production environment

It all starts with an in-depth listening and analysis phase.

We study :

- the type of machine used,

- the material to be cut (steel, stainless steel, aluminium, engineering plastics, etc.),

- product geometry (thickness, diameter, hardness),

- rotation and feed speeds,

- desired cutting quality (tolerances, absence of burrs, brightness, surface finish).

This analysis enables us to understand how you currently work, identify your real constraints, and determine the key parameters of your process.

It all starts with an in-depth listening and analysis phase.

Our technicians study :

- the type of machine used,

- the material to be cut (steel, stainless steel, aluminium, engineering plastics, etc.),

- product geometry (thickness, diameter, hardness),

- rotation and feed speeds,

- desired cutting quality (tolerances, absence of burrs, brightness, surface finish).

This analysis enables us to understand how you currently work, to identify your real constraints, and to determine the key parameters of your process.

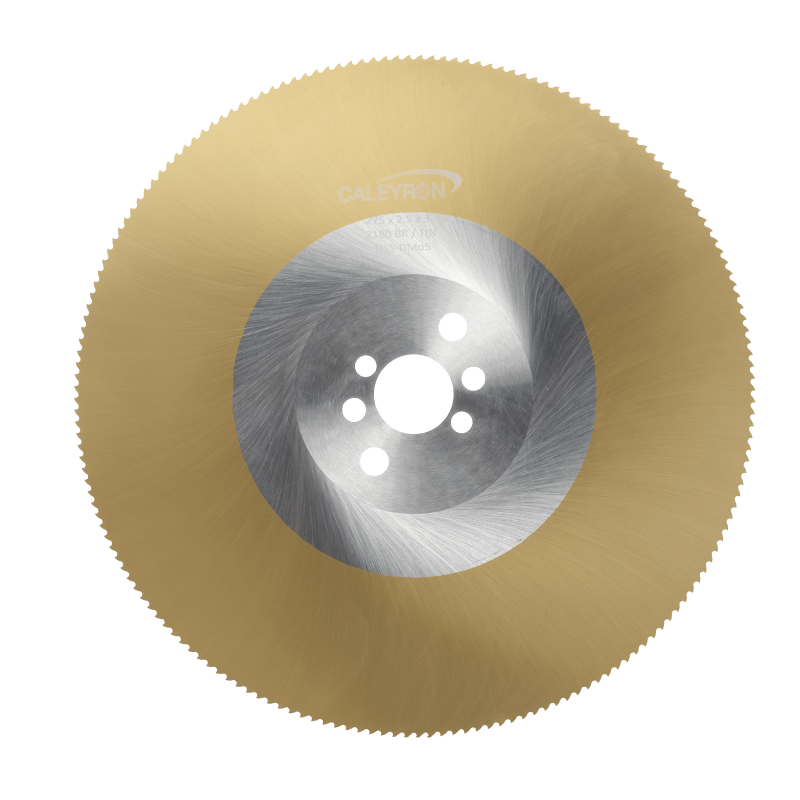

Designing the ideal saw blade: geometry, teeth, coating

Based on this analysis, we design a saw blade to suit your real needs. :

- Blade type: circular cutter-saw, circular knife, special cutter-saw.

- Tool material:

- Solid carbide

- HSS high-speed steel

- Exact dimensions compatible with your machine

- The most suitable tooth form for your material and the desired cut quality

- Coating (TiN, TiAlN, CrN, AlCrN...) to improve service life and reduce friction;

- And finally, recommended cutting parameters to get the most out of your tool.

Every tool we make is the result of engineering and field experience, not a standard choice.

Test, validation and adjustment

We then offer tocarry out real tests on your production line.

These tests enable us to :

- validate the blade's performance under your exact conditions;

- observe cutting condition, surface quality and stability;

- adjust parameters or geometry if necessary.

This collaborative effort is essential to guarantee a reliable, durable solution that has been validated in the field.

Example: adapting a circular saw blade to a specific machine

One of our customers wanted to adapt a new blade to a machine already in service.

The aim was to improve productivity and cleanliness of cut.

We studied their machines, their current cutting conditions and the tools they use. Based on these elements, we definedthe type of blade, its dimensions, its teeth and the most appropriate coating. We also recommended the ideal cutting parameters (speed, feed, depth of cut).

As a result, the new saw blade has reduced machine downtime, extended service life and significantly improved cutting quality.

Example prospect: solving a complex cutting problem

Another typical case: a prospect contacted us because the cut quality of his products was insufficient. The cuts were irregular, the milling machine heated up and produced particles.

After a thorough diagnosis, we identified several factors:

unsuitable blade positioning, incorrectly calibrated cutting parameters and unsuitable tooth geometry.

We then recommended several adjustments to the machine and proposed a cutting test with our tools.

The results were clear: clean cuts, reduced particulate pollution and increased production stability.

Precision at the heart of our manufacturing

At Caleyron Industries, we manufacture a wide range of cutting tools:

- Circular saw blades in HSS high-speed steel and solid carbide,

- Circular knives for precision slitting and cutting,

- Special saw-cutters: alternating teeth, conical, isosceles, ½ round convex or concave.

We also offer a complete hobbing and resharpening service, to extend the life of your tools, as well as coatings adapted to your production conditions.

Each tool is carefully designed in France to your technical specifications.

A lasting technical partnership

Our support doesn't end with the delivery of the tool.

We stay by your side to monitor performance over time, sharpen your circular saw cutters, adjust parameters if your production evolves, and suggest optimizations as your needs change.

It's this technical proximity and responsiveness that are our strengths today.

We don't just sell a cutting tool.

We work with you to build a complete solution to improve the quality, productivity and reliability of your cutting operation.

If you have any questions or need advice about your circular saw blades, don' t hesitate to contact us!