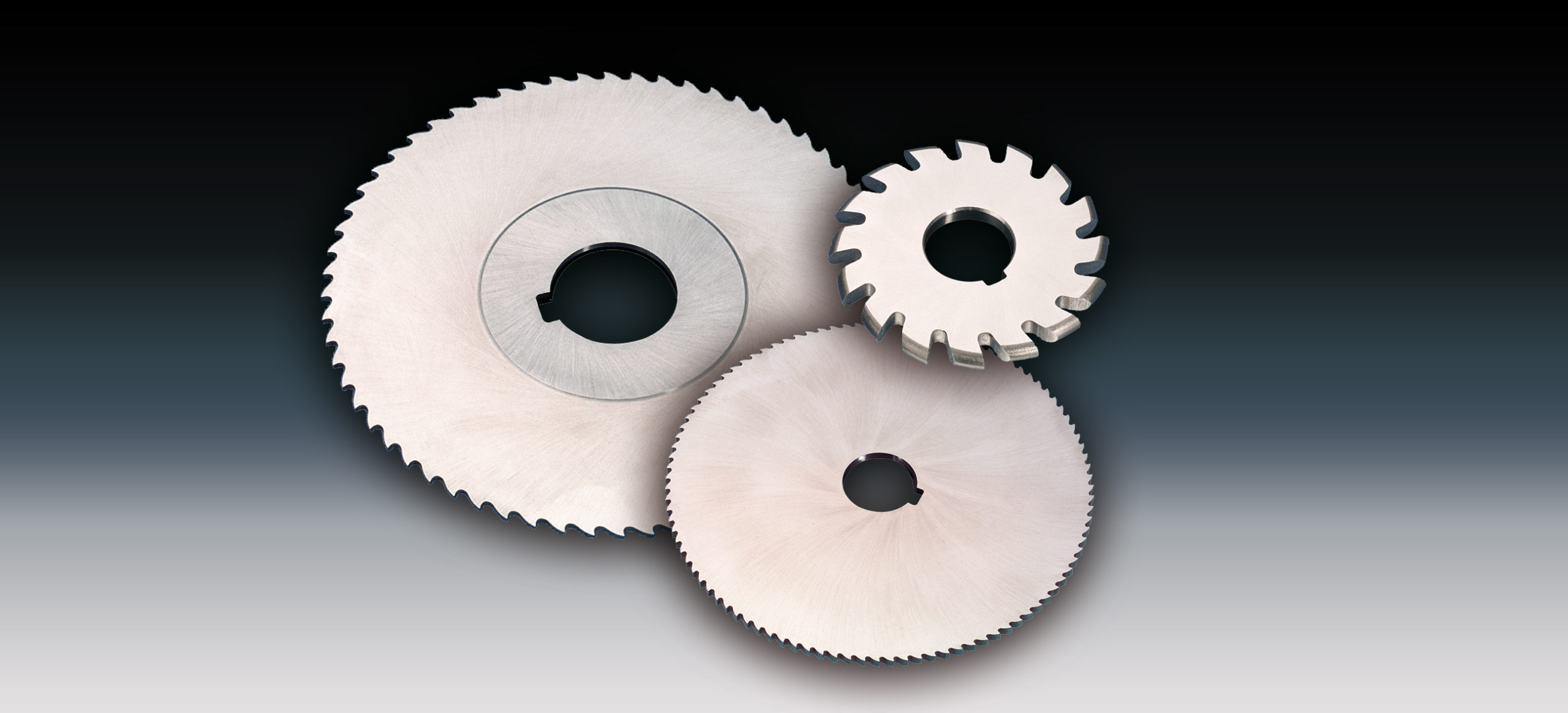

Sharpening of circular saw blades and circular knives

Saw blades and circular knives are intensively used tools for cutting steel or softer materials such as cardboard, rubber, and more. Sharpening cutting tools helps optimize or restore the original cutting precision.

Ensuring a clean and precise cut

Sharpening is a complex operation that requires specific expertise. It must be tailored to both the applications and the materials being machined.

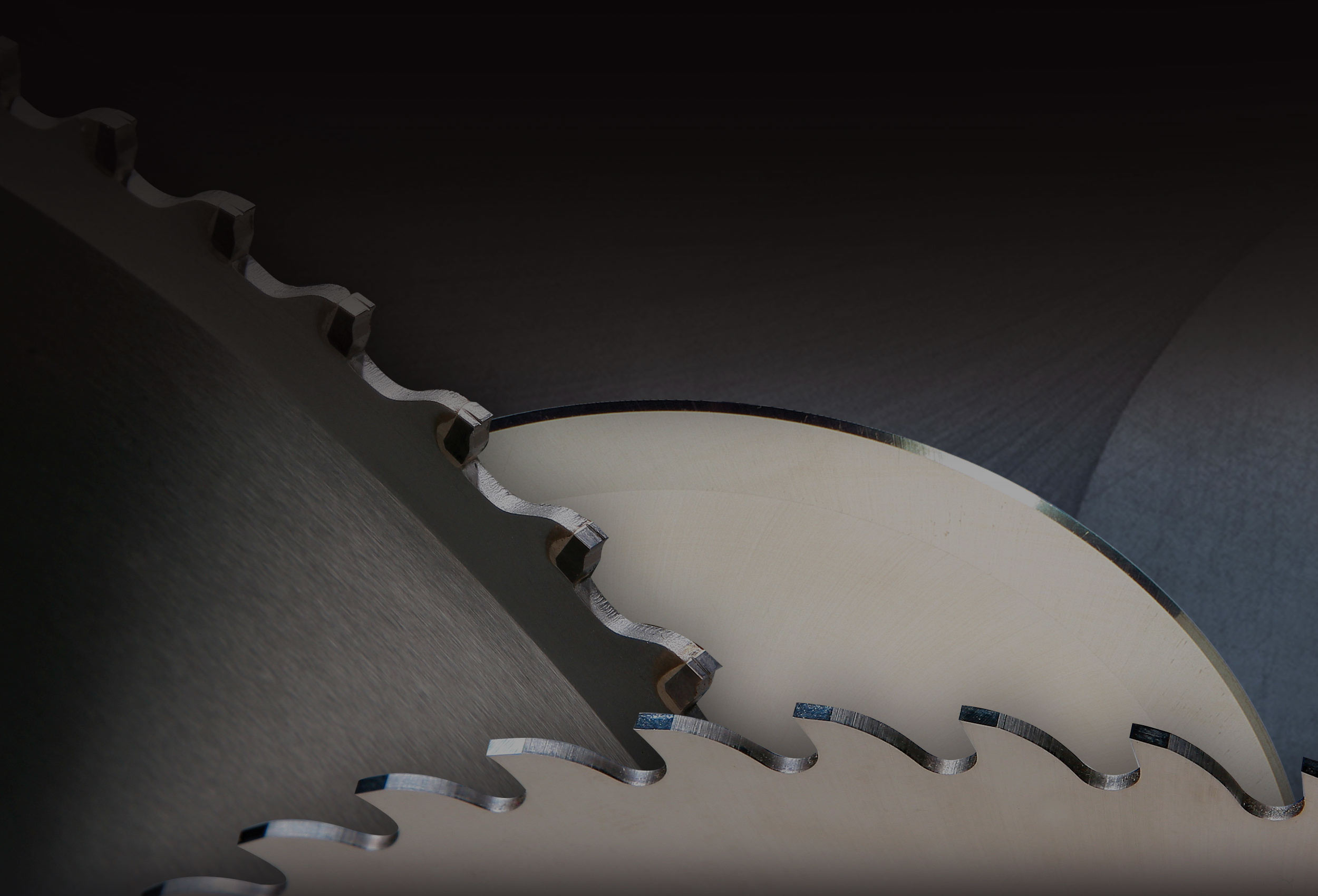

The sharpening of circular saw blades is carried out using state-of-the-art machines.

How to sharpen a circular saw blade or a circular knife?

There are 3 essential steps to ensure your saw blades and circular knives regain their optimal performance after the sharpening process:

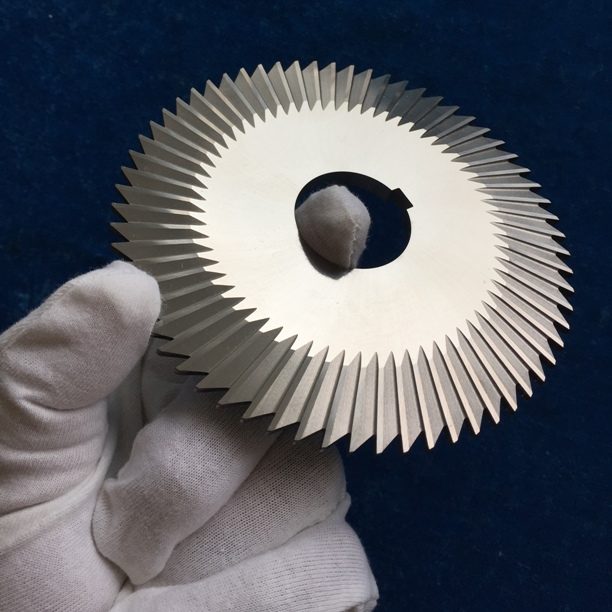

Thorough Inspection

Our team performs a meticulous inspection of circular saw blades and circular knives. This evaluation aims to detect any irregularities, roughness, or deformation, while ensuring that these tools are suitable for the sharpening process.

Wear Correction

Any wear and alterations detected are rectified using a highly precise sharpening machine. This step is crucial to restore the geometry and sharpness of the blades.

Tooth Restoration

The restoration of the teeth on circular saw blades and circular knives is carried out with extreme precision. This ensures their efficiency and longevity. We make sure that each tooth is perfectly sharpened. This phase undergoes rigorous quality checks to maintain high standards.

What types of blades can we sharpen?

Sharpening of standard and special saw blades, circular knives.

- HSS slitting saws

- Solid carbide slitting saws

- ½ round convex slitting saws

- Radius slitting saws

- ½ round concave slitting saws

- Conical slittng saws

- Isosceles slitting saws

- Alternating tooth slitting saws

- Circular knives

When should you sharpen your circular knives and blades?

Sharpening your saw blades and circular knives regularly is essential to maintain their optimal performance and extend their lifespan. The crucial question is: When should you sharpen them?

The answer depends on various factors, but here are some indicators to guide you:

- Loss of cutting efficiency;

- Poor surface finish on the machined part;

- Your tools cause burns on the material you're cutting or generate chips;

- Regular use of your saw blades and circular knives.

A blade that is regularly sharpened will perform much better when in use. A well-maintained sharp tool ensures the safety of users by reducing the risk of generating chips and accidents during cutting.

Do you need reliable and precise cutting tools?

Trust the sharpening of your cutting tools to Caleyron Industries.

Advantages of Our Industrial Sharpening Service

By relying on our professional team, you can outsource the restoration of your cutting tools. Our experience across all industrial sectors guarantees you impeccable service.

Sharpening carbide or HSS circular knives requires high precision. Each operation includes a preliminary diagnosis to assess the condition of the blades. The sharpening of cutting tools is carried out using state-of-the-art equipment to achieve optimal results. This process restores the tools to a like-new condition and restores their original functionality.

Circular Saw Blade and Circular Knife Sharpening Company

The cutting quality of a circular knife or saw cutter is crucial to achieving clean and precise cuts. Sharpening cutting tools is performed on special machines that ensure perfect cutting edge sharpness. We pay special attention to the quality of surface finishes.

CALEYRON INDUSTRIES, with its expertise in cutting tools, offers a sharpening service for industrial professionals. Our promise is to optimize your production lines by enhancing the performance and longevity of your machine tools.

Cutting tools, such as circular saw blades and circular knives, are essential in many industries and are a significant cost. Sharpening cutting tools helps extend their lifespan and delays their replacement.

The importance of regular sharpening provides a range of benefits that improve both efficiency and profitability. It must always be tailored to the industrial applications of the tool.

Do you need reliable and durable cutting tools?

Advice on the type of blade to use, the ideal coating…

Our experts are here to listen and offer personalized recommendations to ensure you choose the best solution for your needs.