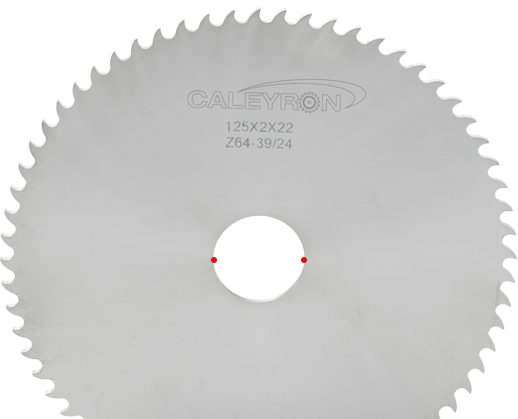

HSS and HSS-E circular saw blades

Our circular saw blades, made in high-speed steel (HSS) are manufactured according to DIN standards to guarantee performance. We also create custom tools tailored to meet your specific cutting needs.

Our range of HSS and HSS--E circular saw blades

Caleyron Industries manufactures a wide range of high speed steel circular saw blades from Ø 20 to Ø 600 mm with thicknesses ranging from 0.2 to 6 mm, for cold cutting technology.

HSS M2 circular saw blades

Made from M2 high-speed steel, these blades are particularly suitable for cutting a wide range of materials, including :

- Mild steels up to a strength of 600 N/mm²,

- Medium steels with strengths between 700 and 900 N/mm²,

- Non-ferrous metals such as brass, copper and aluminum.

Circular saw blades HSS-E M35 (Co5)

Made from 5% cobalt-enriched high-speed steel (M35), these blades offer excellent heat resistance and superior durability. They are ideal for hard-to-machine materials such as :

- Stainless steel (INOX),

- Inconel,

- And, more generally, hard steels.

These blades are particularly recommended for applications on orbital cutting machines, thanks to their robustness and ability to maintain high performance under severe mechanical stress.

To optimize performance and extend service life, we offer a variety of surface coatings. These coatings improve wear resistance, reduce friction and increase cutting speed, even under demanding conditions.

Our coatings

Do you need advice on choosing the right coating for your tools?

We offer our expertise and testing resources to support you in your optimization process,

helping you select the best coating for your tools and applications.

Toothforms

DIN 1837 - A

A - Fine-toothed

AW - Alternating beveled teeth

One tooth beveled to the left, one tooth beveled to the right

Shape A is used for cutting thin sections or making shallow grooves.

Shape AW helps to break up chips for better evacuation.

DIN 1838 - B

B - Coarse-toothed

BW - Alternating beveled teeth

One tooth beveled to the left, one tooth beveled to the right

Shape B is used for cutting thick sections or making deep grooves.

Shape BW helps to break up chips for better evacuation.

DIN 1838 - C

C - Alternating beveled teeth

One tooth beveled to the left, one tooth beveled to the right

Shape C is used for deep grooving, thanks to its profile, which allows for chip breaking and reduced cutting forces.

Dimensions of HSS and HSS-E circular saw blades

DIN 1837

| Thickness | 0.2 | 0.25 | 0.3 | 0.4 | 0.5 | 0.6 | 0.8 | 1 | 1.2 | 1.6 | 2 | 2.5 | 3 | 4 | 5 | 6 | |

| Diam. | Bore | Number of teeth | |||||||||||||||

| 20 | 5 | 80 | 64 | 64 | 64 | 48 | 48 | 48 | 40 | 40 | 40 | 32 | 32 | 32 | 24 | 24 | 24 |

| 25 | 8 | 80 | 80 | 80 | 64 | 64 | 64 | 48 | 48 | 48 | 40 | 40 | 40 | 32 | 32 | 32 | 24 |

| 32 | 8 | 100 | 100 | 80 | 80 | 80 | 64 | 64 | 64 | 48 | 48 | 48 | 40 | 40 | 40 | 32 | 32 |

| 40 | 10 | 128 | 128 | 100 | 100 | 80 | 80 | 80 | 64 | 64 | 64 | 48 | 48 | 48 | 40 | 40 | 40 |

| 50 | 13 | 128 | 128 | 128 | 100 | 100 | 100 | 80 | 80 | 80 | 64 | 64 | 64 | 48 | 48 | 48 | 40 |

| 63 | 16 | 160 | 128 | 128 | 128 | 100 | 100 | 100 | 80 | 80 | 80 | 64 | 64 | 64 | 48 | 48 | |

| 80 | 22 | 160 | 128 | 128 | 128 | 128 | 100 | 100 | 100 | 80 | 80 | 80 | 64 | 64 | 64 | ||

| 100 | 22 | 160 | 160 | 128 | 128 | 128 | 100 | 100 | 100 | 80 | 80 | 80 | 64 | ||||

| 125 | 22 | 160 | 160 | 160 | 128 | 128 | 128 | 100 | 100 | 100 | 80 | 80 | |||||

| 150 | 32 | 160 | 160 | 160 | 128 | 128 | 128 | 128 | 100 | 100 | |||||||

| 160 | 32 | 160 | 160 | 160 | 128 | 128 | 128 | 128 | 100 | 100 | |||||||

| 200 | 32 | 200 | 200 | 160 | 160 | 160 | 128 | 128 | 128 | 100 | |||||||

| 250 | 32 | 200 | 200 | 160 | 160 | 160 | 128 | 128 | |||||||||

| 315 | 32 | 200 | 200 | 160 | 160 | 160 | |||||||||||

DIN 1838

| Thickness | 0.2 | 0.25 | 0.3 | 0.4 | 0.5 | 0.6 | 0.8 | 1 | 1.2 | 1.6 | 2 | 2.5 | 3 | 4 | 5 | 6 | |

| Diam. | Bore | Number of teeth | |||||||||||||||

| 20 | 5 | 24 | 24 | 24 | 20 | 20 | 20 | ||||||||||

| 25 | 8 | 32 | 32 | 24 | 24 | 24 | 20 | 20 | 20 | ||||||||

| 32 | 8 | 30 | 30 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | ||||

| 40 | 10 | 40 | 40 | 40 | 32 | 32 | 32 | 24 | 24 | 24 | 20 | 20 | 20 | ||||

| 50 | 13 | 48 | 48 | 40 | 40 | 40 | 32 | 32 | 32 | 24 | 24 | 24 | 20 | ||||

| 63 | 16 | 64 | 48 | 48 | 48 | 40 | 40 | 40 | 32 | 32 | 32 | 24 | 24 | ||||

| 80 | 22 | 64 | 64 | 64 | 48 | 48 | 48 | 40 | 40 | 32 | 32 | 32 | 32 | ||||

| 100 | 22 | 80 | 80 | 64 | 64 | 64 | 48 | 48 | 48 | 40 | 40 | 40 | 32 | ||||

| 125 | 22 | 80 | 80 | 80 | 64 | 64 | 64 | 48 | 48 | 48 | 40 | 40 | |||||

| 150 | 32 | 80 | 80 | 80 | 64 | 64 | 64 | 64 | 48 | 48 | |||||||

| 160 | 32 | 80 | 80 | 80 | 64 | 64 | 64 | 48 | 48 | 48 | |||||||

| 200 | 32 | 100 | 100 | 80 | 160 | 80 | 64 | 64 | 64 | 48 | |||||||

| 250 | 32 | 100 | 100 | 80 | 80 | 80 | 64 | 64 | |||||||||

| 315 | 32 | 100 | 100 | 80 | 80 | 80 | |||||||||||

Do you need a made-to-measure blade?

Depending on your requirements, we can produce teeth with customised dimensions (non-standard)