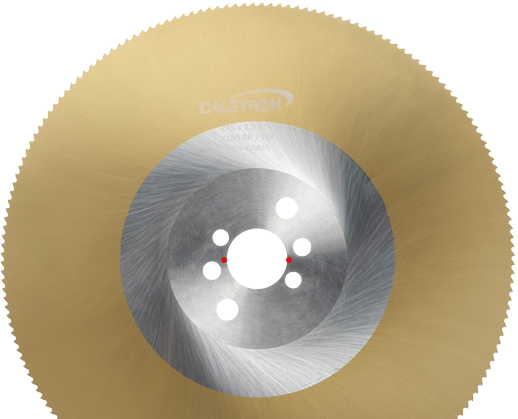

Cut-off circular saw blades

Our cutting-off saw blades are designed to deliver exceptional cutting performance, even in the most demanding conditions.

Ideal for industrial and professional applications, they ensure clean, fast, and precise cuts on various materials such as steel, aluminum, and other metals.

Our range of cut-off circular saw blades

Caleyron Industries manufactures a wide range of cut-off circular saw blades according to your specific needs, in HSS and HSS-E M35 from Ø 175 to Ø 700 mm.

Designed to withstand wear and high temperatures, they ensure enhanced durability and consistent cutting quality.

Applications

Cut-off saw blades are commonly used in industries where cutting precision and speed are crucial.

Metallurgical Industry / Automotive and Aerospace / Machine and Equipment Manufacturing: Cutting of various metals (steel, aluminum, copper), metal profiles, tubes, bars...

They are also essential in production lines where metals or hard materials are transformed into specific parts or components.

Materials to be cut

- Non-ferrous metals such as copper, brass, and aluminium

- Steel and Stainless Steel: Designed for cutting hard steels

Tailored service

Our cut-off blades can be custom-tailored in terms of diameter, thickness, and coating to precisely match the needs of each application.

Our coatings

Do you need advice on choosing the right coating for your tools?

We offer our expertise and testing resources to support you in your optimization process,

helping you select the best coating for your tools and applications.

Toothforms

DIN 1838 - BW

BW - Tooth profile with alternating chamfers

A left chamfered tooth, a right chamfered tooth.

The BW tooth profile allows for chip segmentation, ensuring better chip evacuation..

DIN 1838 - C

C - Tooth profile with alternating chamfers

A high chamfered tooth on both sides and a low non-chamfered tooth.

The C tooth profile is used for deep grooving, as its design allows for chip segmentation and reduces cutting forces.

Dimensions

| Ø | Thickness | Bore | HUB | Number and shape of the teeth | |||||||||

| T3 | T4 | T5 | T6 | T7 | T8 | T10 | T12 | T14 | T16 | ||||

| 175 | 1,2 | 32 | 75 | 180 BW | 140 BW | 100 C | 90 C | 80 C | 70 C | ||||

| 1,5 | 32 | 76 | 180 BW | 140 BW | 100 C | 90 C | 70 C | ||||||

| 2 | 32 | 77 | 180 BW | 140 BW | 100 C | 80 C | 80 C | ||||||

| 200 | 1.8 | 32 | 90 | 200 BW | 160 BW | 120 C | 100 C | 80 C | |||||

| 2 | 32 | 91 | 200 BW | 160 BW | 120 C | 100 C | 80 C | ||||||

| 225 | 1,2 | 32 | 100 | 220 BW | 180 BW | 140 C | 120 C | 90 C | |||||

| 1,5/1,6 | 32 | 90 | 220 BW | 180 BW | 140 C | 120 C | 90 C | ||||||

| 2 | 32 | 90 | 220 BW | 180 BW | 140 C | 120 C | 90 C | ||||||

| 250 | 1 | 32 | 100 | 240 BW | 200 BW | 160 C | 128 C | 110 C | 100 C | 80 C | |||

| 1.2 | 32 | 100 | 240 BW | 200 BW | 160 C | 128 C | 110 C | 80 C | |||||

| 1,5/1,6 | 32/40 | 100 | 240 BW | 200 BW | 160 C | 128 C | 110 C | 100 C | 80 C | ||||

| 2 | 32/40 | 100 | 240 BW | 200 BW | 160 C | 128 C | 100 C | 80 C | |||||

| 2.5 | 32/40 | 100 | 240 BW | 200 BW | 160 C | 128 C | 110 C | 100 C | 80 C | ||||

| 275 | 1.2 | 32 | 100 | 280 BW | 220 BW | 180 C | 140 C | 120 C | 110 C | 90 C | |||

| 1.6 | 32 | 100 | 280 BW | 220 BW | 180 C | 140 C | 120 C | 110 C | 90 C | ||||

| 2 | 32/40 | 100 | 280 BW | 220 BW | 180 C | 140 C | 120 C | 110 C | 90 C | ||||

| 2.5 | 32/40 | 100 | 280 BW | 220 BW | 140 C | 120 C | 110 C | 90 C | |||||

| 3 | 32/40 | 100 | 280 BW | 220 BW | 180 C | 140 C | 110 C | 90 C | |||||

| 300 | 1.6 | 32 | 100 | 300 BW | 220 BW | 180 C | 160 C | 120 C | 90 C | ||||

| 2 | 32/40 | 100 | 300 BW | 220 BW | 180 C | 160 C | 120 C | 90 C | |||||

| 2.5 | 32/40 | 100 | 300 BW | 220 BW | 180 C | 160 C | 120 C | 90 C | |||||

| 3 | 32/40 | 100 | 300 BW | 220 BW | 180 C | 160 C | 120 C | 90 C | |||||

| 315 | 1.6 | 32 | 100 | 320 BW | 240 BW | 200 C | 160C | 120 C | 100 C | 80 C | |||

| 2 | 32/40 | 100 | 320 BW | 240 BW | 200 C | 160C | 120 C | 100 C | 80 C | ||||

| 2.5 | 32/40 | 100 | 320 BW | 240 BW | 160C | 120 C | 100 C | 80 C | |||||

| 3 | 32/40 | 100 | 320 BW | 240 BW | 200 C | 160C | 120 C | 100 C | 80 C | ||||

| 325 | 2.5 | 32/40 | 120 | 320 BW | 250 BW | 200 C | 170 C | 128 C | 100 C | ||||

| 3 | 32/40 | 120 | 320 BW | 250 BW | 200 C | 170 C | 128 C | 100 C | |||||

| 350 | 1.8 | 32/40 | 120 | 350 BW | 280 BW | 220 C | 180 C | 160 C | 140 C | 110 C | 90 C | ||

| 2 | 32/40 | 120 | 350 BW | 280 BW | 220 C | 180 C | 160 C | 140 C | 110 C | 90 C | |||

| 2.5 | 32/40/50 | 350 BW | 280 BW | 220 C | 180 C | 160 C | 140 C | 110 C | 90 C | ||||

| 3 | 32/40/50 | 120 | 350 BW | 280 BW | 220 C | 180 C | 160 C | 140 C | 110 C | 90 C | |||

| 370 | 2 | 32/40/50 | 120 | 380 BW | 280 BW | 220 C | 190 C | 160 C | 140 C | 110 C | 100 C | ||

| 2.5 | 32/40/50 | 120 | 380 BW | 280 BW | 220 C | 190 C | 160 C | 140 C | 110 C | 100 C | |||

| 3 | 32/40/50 | 380 BW | 280 BW | 220 C | 190 C | 160 C | 110 C | 100 C | |||||

| 400 | 2 | 32/40/50 | 120 | 310 BW | 250 C | 200 C | 160 C | 120 C | 100 C | ||||

| 2.5 | 120 | 310 BW | 250 C | 200 C | 160 C | 120 C | 100 C | ||||||

| 3 | 32/40/50 | 120 | 310 BW | 250 C | 200 C | 160 C | 120 C | 100 C | |||||

| 3.5 | 40/50 | 120 | 310 BW | 250 C | 200 C | 160 C | 120 C | 100 C | |||||

| 4 | 40/50 | 120 | 310 BW | 250 C | 200 C | 160 C | 120 C | 100 C | |||||

| 425 | 2.5 | 40/50 | 120 | 320 BW | 260 C | 220 C | 160 C | 130 C | 100 C | ||||

| 3 | 40/50 | 120 | 320 BW | 260 C | 220 C | 160 C | 130 C | 100 C | |||||

| 3.5 | 40/50 | 120 | 320 BW | 260 C | 220 C | 160 C | 130 C | 100 C | |||||

| 4 | 40/50 | 120 | 320 BW | 260 C | 220 C | 160 C | 130 C | 100 C | |||||

| 450 | 2.5 | 40/50 | 130 | 350 BW350 BW | 280 C | 230 C | 180 C | 140 C | 120 C | 90 C | |||

| 3 | 40/50 | 130 | 350 BW | 280 C | 230 C | 180 180 CC | 140 C | 120 C | 90 C | ||||

| 3.5 | 40/50 | 130 | 350 BW | 280 C | 2230 C30 C | 180 C | 140 C | 120 C | 90 C | ||||

| 4 | 40/50 | 130 | 350 BW | 280 C | 230 C | 180 C | 140 C | 120 C | 90 C | ||||

| 500 | 3 | 40/50 | 130 | 390 BW | 310 C | 260 C | 200 C | 160 C | |||||

| 3.5 | 40/50 | 130 | 390 BW | 310 C | 260 C | 200 C | 160 C | ||||||

| 4 | 40/50 | 130 | 390 BW | 310 C | 260 C | 200 C | 160 C | ||||||

| 525 | 3.5 | 50 | 140 | 410 BW | 330 C | 270 C | 210 C | 164 C | |||||

| 4 | 50 | 140 | 410 BW | 330 C | 270 C | 210 C | 164 C | ||||||

| 550 | 3.5 | 50/90/140 | 200/225 | 340 C | 280 C | 250 C | 220 C | 170 C | 140 C | 120 C | |||

| 4 | 50/90/140 | 200/225 | 340 C | 280 C | 220 C | 170 C | 140 C | 120 C | |||||

| 570 | 3.5 | 50 | 180 | 360 C | 300 C | 220 C | 180 C | ||||||

| 4 | 50 | 180 | 300 C | 220 C | 190 C | ||||||||

| 600 | 3.5 | 50/90/140 | 200/225 | 380 C | 320 C | 240 C | 190 C | 160 C | 130 C | ||||

| 4 | 50/90/140 | 200/225 | 380 C | 320 C | 240 C | 190 C | 160 C | 130 C | |||||

| 625 | 4 | 50/90/140 | 200/225 | 390 C | 320 C | 280 C | 240 C | 190 C | 160 C | 140 C | |||

| 650 | 4 | 80 | 225 | 340 C | 250 C | 200 C | 170 C | 150 C | |||||

| 700 | 4 | 80 | 225 | 360 C | 260 C | 200 C | 180 C | 160 C |

Do you need a made-to-measure blade?

Depending on your requirements, we can produce teeth with customised dimensions (non-standard)