Circular saw blade: which one for non-ferrous metals?

Publié le 15 April 2025

When it comes to cutting non-ferrous metals such as aluminum, copper, zinc or titanium, the choice of circular saw blade is all the more important. These materials have specific characteristics that influence the quality and precision of the cut, depending on the blade used. Using an unsuitable blade can lead to overheating, burrs or premature tool wear.

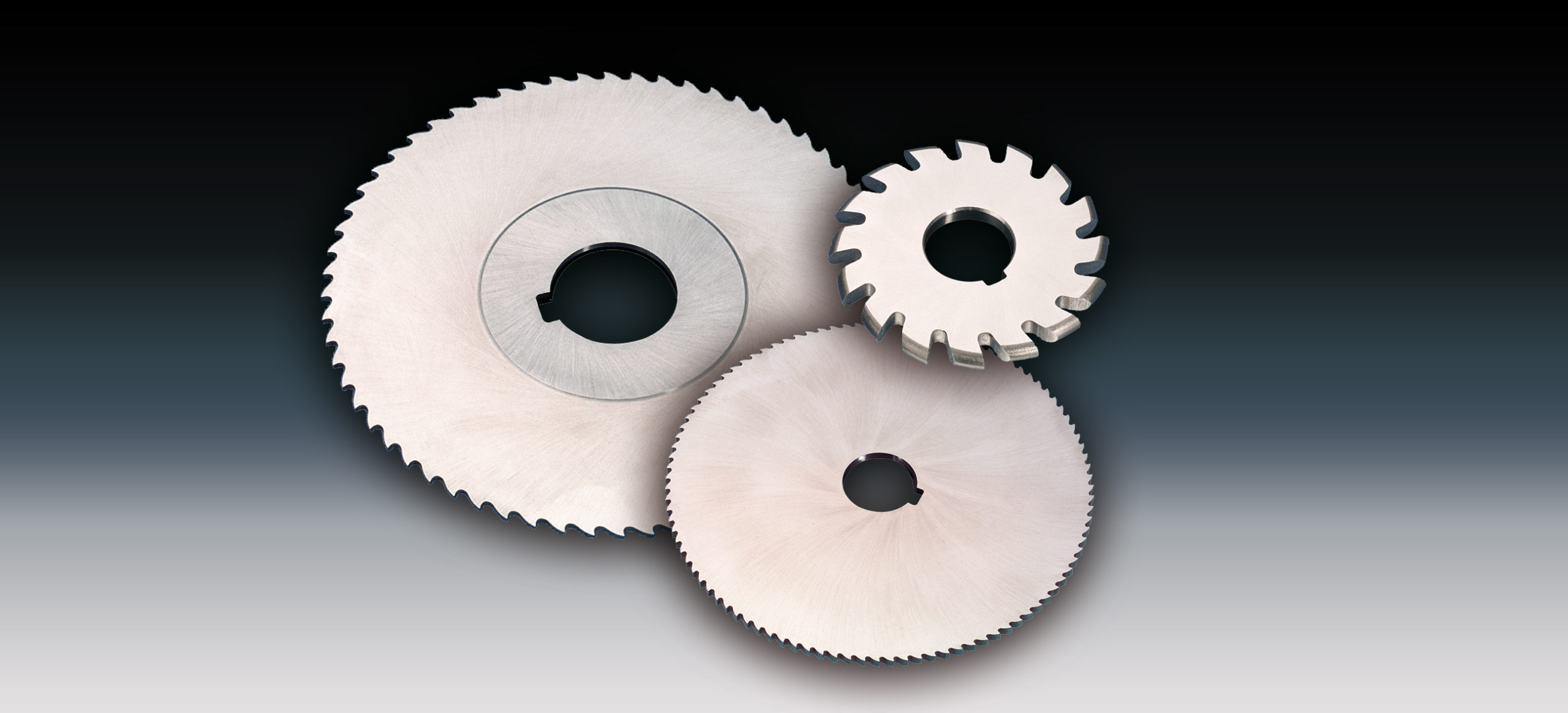

At Caleyron Industries, we manufacture solid carbide circular blades and HSS circular saw bladeshigh-speed steel, adapted to the needs of industry and the cutting of non-ferrous materials. We serve a wide range of industrial sectors , offering both standard (DIN) and customized circular saw blades.

Non-ferrous metals and their cutting constraints

Non-ferrous metals are distinguished from other materials by their resistance to corrosion and their variable mechanical properties due to the virtual absence of iron in their composition. The most common machined materials containing no iron are :

- Aluminum: one of the most common. It's light and machinable, but tends to stick to saw teeth due to its ductility.

- Copper: highly conductive to heat and electricity, making cutting difficult.

- Zinc and lead: these are soft metals requiring low cutting speeds to limit distortion and burrs.

- Titanium and nickel: highly resistant metals that generate considerable heat and wear on cutting tools.

What parameters influence the choice of circular saw blade?

The choice of a blade depends on a number of criteria which must be carefully evaluated in order to obtain an optimum cut. First of all, it's essential to consider the type of action to be performed. A blade designed for cross-cutting should guarantee a clean, straight cut through the entire thickness of the material, while a blade designed for grooving should enable the creation of precise grooves for assemblies or finishes. Scribing, on the other hand, requires a specific blade capable of smoothly rounding off edges.

At the same time, the type of machine and its settings greatly influence cutting performance. The speed of rotation, expressed in revolutions per minute (rpm), must be adjusted according to the hardness of the metal: the softer the material, the higher the speed can be. Cutting speed, measured in meters per minute (m/min), must be calibrated to ensure a good compromise between efficiency and tool life. Finally, feed speed must be adapted to the nature of the metal being worked; for example, a slower feed rate is recommended for hard metals such as titanium, to avoid premature wear of the blade.

Which circular blade for non-ferrous materials?

To cut these metals efficiently, it is crucial to select the right circular saw blade.

High-speed steel (HSS) or solid carbide blades?

HSS blades are more flexible and affordable, ideal for soft metals such as zinc and lead. However, they wear more quickly on harder materials. Solid carbide blades offer superior strength and a clean cut, and are recommended for aluminum, copper and titanium.

TCT and CERMET blades: when to choose?

TCT blades (carbide inserts) are designed for intensive, precise cutting on metals such as aluminum. They reduce wear and increase tool life. CERMET blades, on the other hand, are particularly suited to hard alloys such as titanium and nickel, thanks to their thermal resistance.

Which teeth and shape to choose?

The choice of teeth and blade shape has a direct influence on the quality and precision of the cut, and depends on the action you wish to perform. For example, for a clean cut on aluminum and copper, alternating teeth are ideal. On the other hand, 1-cut conical cutters are particularly suitable for grooving operations in zinc alloys, for example. For precise, smooth finishes on titanium and nickel, helical cutters are recommended. Finally, for radiusing operations, ½ round convex or concave cutters offer optimum results.

Note: Management and optimization of cutting parameters

In addition to the choice of blade, it is essential to adapt the cutting parameters. The speed of rotation must be adjusted according to the hardness of the metal. Effective lubrication reduces overheating and improves precision. Last but not least, the choice of gearing has a direct influence on cutting quality: fine gearing is best suited to precise cuts, e.g. smaller sections or shallower depths, while alternating gearing is preferable for aluminum to break up chips for better evacuation.

The choice of circular saw blade depends on the type of metal to be cut and the machining parameters. Solid carbide and TCT blades are recommended for the most commonly machined non-ferrous metals, while CERMET blades are more suitable for tougher metals. The right combination of blade and cutting parameters will guarantee optimum performance and extended tool life.

Need a specific blade for your applications?