HSS vs solid carbide: differences, advantages and industrial applications

Publié le 20 January 2026

Choosing between an HSS and a solid carbide blade is one of the most frequently asked questions in the cutting tool industry. This choice has a direct impact on cutting quality, tool life, productivity and overall operating costs.

In this article, we offer a clear, technical and accessible comparison between HSS (high-speed steel) and solid carbide, to help you choose the solution best suited to your application.

What is an HSS (high-speed steel) blade?

HSS - High Speed Steel- is a high-alloy steel designed to maintain good mechanical properties even at higher cutting speeds and temperatures.

In practical terms, an HSS blade offers a good balance between mechanical strength and ease of sharpening. It tolerates shocks, vibrations and imperfect cutting conditions relatively well. This is why it is still widely used in many industrial applications, notably for circular saw blades and circular knives subjected to variable stress.

Its lower purchase price also makes it a popular solution when production rates remain reasonable, or when the machine cannot fully exploit more technical materials.

What is a solid carbide blade?

Solid carbide is a sintered material based on tungsten carbide, renowned for its extremely high hardness and resistance to wear. Unlike tools with inserts, a solid carbide blade is made entirely of carbide.

This type of blade is particularly well suited to demanding industrial environments, where precision, cutting consistency and tool life are decisive criteria. Thanks to its structure, solid carbide enables us to work at higher cutting speeds while maintaining consistent cutting quality over time.

Key differences between HSS and solid carbide

| Criteria | HSS blade | Solid carbide blade |

|---|---|---|

| Hardness | Medium | Very hard |

| Wear resistance | Good | Excellent |

| Toughness (impact) | Very good | Weaker |

| Cutting speed | Medium | High |

| Precision | Good | Very high |

| Service life | Medium | Long |

| Initial cost | Lower cost | higher |

| Total cost | Variable | Often more profitable |

Advantages and limitations of HSS blades

HSS blades offer a number of advantages in specific applications. Their high toughness enables them to better withstand mechanical shocks and vibrations, which is particularly advantageous when cutting conditions are not perfectly controlled. They are also a cost-effective solution that is relatively easy to resharpen.

On the other hand, their wear resistance remains limited compared to carbide. In intensive applications or on abrasive materials, wear is more rapid and heating can become a limiting factor.

Advantages and limitations of solid carbide blades

The main advantage of solid carbide is its significantly longer tool life. It enables high cutting quality to be maintained over long production runs, and significantly reduces machine downtime due to tool changes. This stability makes it the preferred choice for high production rates and precision requirements.

On the other hand, solid carbide represents a higher initial investment and requires well-controlled application. A machine that is too flexible, or repeated shocks, can lead to premature breakage if the choice of tool is not perfectly adapted.

HSS or solid carbide: which application to choose?

The choice between HSS and solid carbide depends above all on actual cutting conditions. HSS is generally preferred when speeds are moderate, the application generates shocks or machine rigidity is limited. It is a reliable and cost-effective solution in these situations.

On the other hand, solid carbide is essential when the aim is to increase productivity, extend tool life and guarantee constant precision. It is particularly suited to abrasive materials, high production rates and industrial environments where every machine stoppage has a cost.

HSS or solid carbide: a question of profitability

Although solid carbide represents a higher initial investment, it is often more profitable in the long term:

- fewer replacements

- less machine downtime

- better production regularity

However, HSS remains an excellent solution for certain specific applications or mechanical constraints.

HSS or solid carbide: feedback from the field

In industrial practice, there is no single answer. In our workshop, we regularly find that the choice between HSS and solid carbide depends much more on actual production conditions than on the material alone.

HSS remains a reliable and consistent solution on lines with moderate output, older machines or machines that generate vibrations. It offers good tolerance to setting deviations and ensures stable cutting without over-investment.

Conversely, when cutting parameters are controlled and productivity becomes a key issue, solid carbide clearly takes the lead. In these configurations, we observe a significant reduction in machine downtime, more consistent cutting quality and better control of overall tool costs.

The right choice is therefore based on a comprehensive analysis of material, cutting speed, machine rigidity, output and profitability targets.

Conclusion

Comparing HSS and solid carbide is not a question of opposing good and bad solutions, but of identifying the most suitable tool for a given application.

The right choice not only improves cutting quality, but also optimizes tool life and overall production performance.

Need technical support?

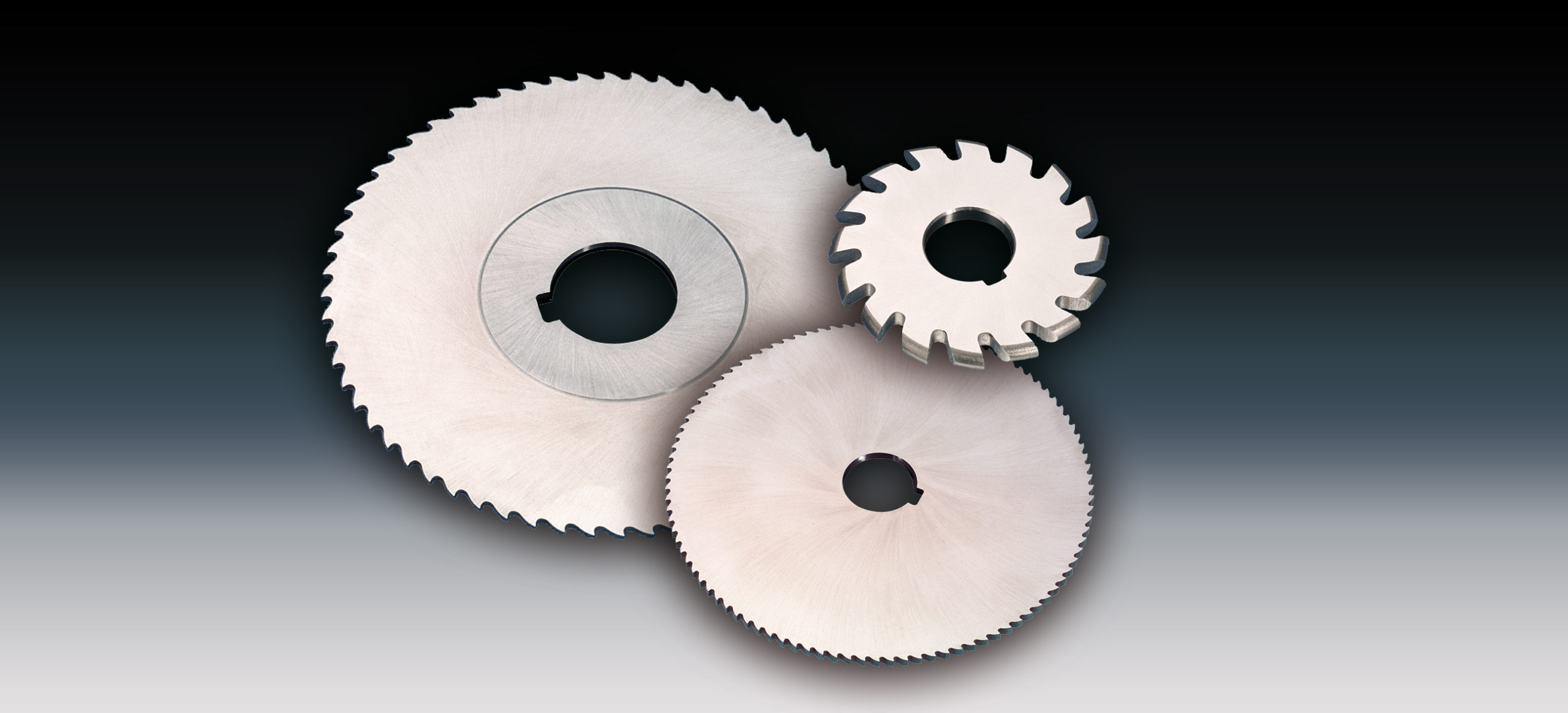

At Caleyron Industries, we manufacture standard and custom HSS and solid carbide blades. We also support our customers in analyzing their applications, and offer a resharpening service to extend tool life.

A technical discussion often leads to the identification of concrete, measurable optimization levers.

FAQ - HSS vs solid carbide

What's the difference between an HSS blade and a solid carbide blade?

The HSS blade is tougher and more shock-tolerant, while the solid carbide blade is much harder, more wear-resistant and offers longer service life.

Should you choose HSS or solid carbide for industrial applications?

The choice depends on cutting speed, material, machine rigidity and cycle rates. HSS is suitable for variable conditions, solid carbide for intensive production.

Is solid carbide more cost-effective than HSS?

Yes, in the long term, as longer service life reduces machine downtime and replacements, despite higher initial costs

Why does a solid carbide blade cut longer?

Thanks to its high hardness and resistance to wear, carbide retains its effective cutting geometry for longer.

Is HSS still used in industry?

Yes, especially for applications with mechanical shocks, vibrations or moderate cutting speeds