Solid carbide (or tungsten carbide): an essential material for modern industry

Publié le 9 September 2025

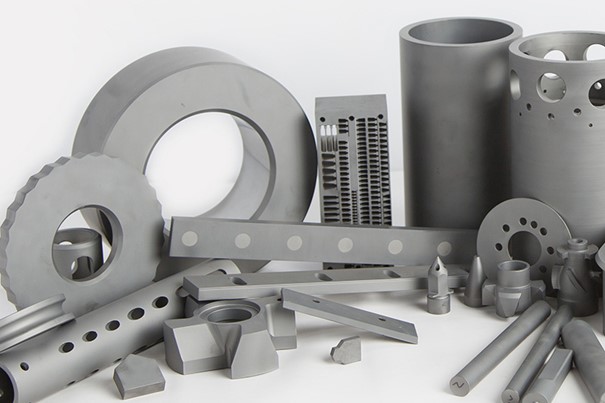

Solid carbide, or hard metal, is an exceptional composite material, obtained by cementing tungsten carbide grains into a cobalt or nickel metal matrix through sintering. This unique combination gives the material remarkable mechanical properties: near-diamond hardness, higher density than steel and titanium, and exceptional wear resistance.

Tungsten carbide, the most widely used variant, is particularly suited to the manufacture ofcutting tools, milling cutters and drills. It is also prized in demanding sectors such as construction, mining and metalworking, for its strength and durability.

The unique properties of carbide

Solid carbide is exceptionally resistant to wear, enabling tools to maintain a precise, long-lasting cutting edge, even on very hard or abrasive materials. Its thermal stability ensures that hardness and precision remain intact when cutting at high speeds or in hot environments.

Modern carbide grades also offer enhanced toughness, reducing the risk of cracking or breaking under high stress. With the addition of advanced coatings such as PVD or CVD, tools can be tailored to specific applications, further enhancing their longevity and efficiency.

The current context and growth drivers

The tungsten carbide market is experiencing strong growth, driven by a number of factors. The increasing use of hard metals and tungsten in various alloys is responding to the ever more demanding performance requirements of industry.

Carbide is widely used in theelectronics,aerospace and defense industries, where precision and strength are crucial. Applications in medical technology, the automotive industry, lighting and the assembly of industrial components also contribute to this expansion.

Solid carbide industrial applications

| Industry | Application |

| Aeronautics and aerospace | it enables the machining of titanium or Inconel parts to exacting tolerances. |

| Automotive | it ensures the manufacture of precise, durable engine parts. |

| Electronics and lighting | tungsten is used for miniaturized components and filaments. |

| Medical technology | it is used to manufacture surgical instruments and implantable devices. |

| Construction, mining and metalworking | for precise cutting and shaping of very hard materials. |

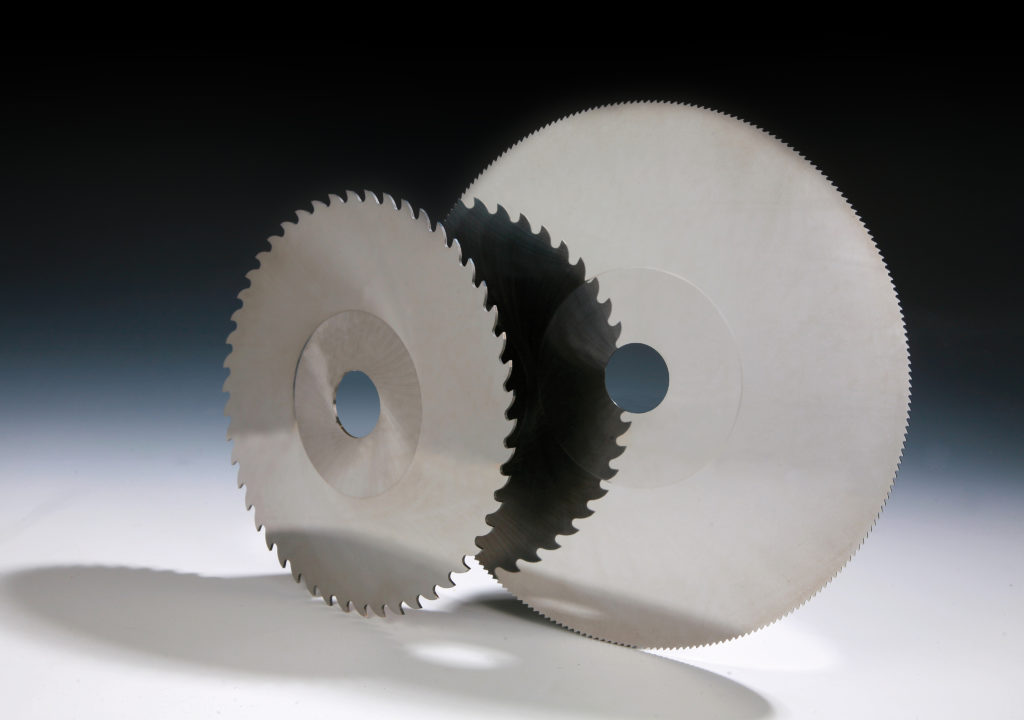

Our solid carbide circular saw blades

At Caleyron Industries, we design and manufacture solid carbide circular saw blades to very tight manufacturing tolerances, comparable to DIN standards, to guarantee performance and reliability. We also offer tailor-made tools, adapted to our customers' specific precision-cutting needs.

A complete range for every need

We produce a wide variety of carbide circular saw blades, available in diameters ranging from Ø 20 mm to Ø 300 mm and thicknesses from 0.2 to 6 mm.

Our blades cover a broad spectrum of applications, from cutting soft metals to the toughest materials.

Grades for industrial applications

Our blades are manufactured with different grades of carbide (K10, K20, K30 and others, depending on your needs).

This diversity enables us to offer the most appropriate solution for the nature of the materials to be machined and the cutting conditions.

- Ø 15 to 300 mm: to suit all production configurations.

- Tight tolerances: guaranteeing precision and regularity of cut.

Enhanced performance and durability

These blades are specially designed for machining high-strength materials such asstainless steel or titanium, enabling particularly high cutting speeds to be achieved.

When used on softer materials, they offer significantly greater durability, reducing the frequency of replacement and optimizing the profitability of operations.

Impeccable finish quality

Each milling cutter is manufactured with a high-quality mirror-polished surface finish.

This finish guarantees :

- a clean, precise cut,

- optimal maintenance of dimensional tolerances,

- reduced friction for longer tool life.

A specialized manufacturing process

Our specific production cycles result in blades with exceptional hardness and high toughness.

They are therefore perfectly suited to the most demanding applications, where precision, performance and longevity are essential criteria.

Conclusion: a strategic material for modern industry

In today's industrial context, where performance, durability and precision are essential, tungsten carbide remains an essential material. Its combination of extreme hardness, wear resistance and thermal stability makes it indispensable for cutting tools and critical components.

Tungsten, the central element of carbide, is increasingly in demand in strategic sectors such asaeronautics, defense, electronics and medicine, confirming its place as a key material in modern industry.