The difference between milling saws and circular knives

Publié le 24 June 2024

Milling saws and circular knives are two essential tools for cutting materials, but they differ in their applications and technical features.

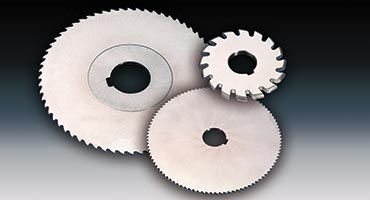

Saw-cutters, often used for metal cutting, are characterized by a tooth system that ensures a clean, burr-free cut. The number of teeth, tooth shape and angles vary according to the application. They are mainly used for cutting structural steels, case-hardened steels, tool steels, free-cutting steels, stainless steels, case-hardened steels, as well as plastics and PVC. They are commonly used for milling and grooving operations.

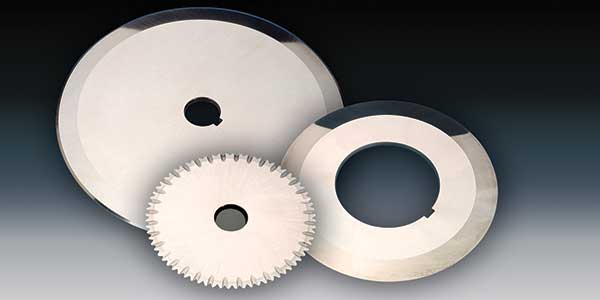

Circular knives are beveled disks. They are used for slicing soft materials and can be equipped with teeth depending on the application.

What is a circular saw cutter?

A circular milling cutter is a cutting tool used mainly in the mechanical industry for machining metals and various materials. It is characterized by a toothed circular blade mounted on a machine, which rotates at high speed to cut materials.

Using circular saw cutters :

- Metal cutting: Circular saw cutters are widely used for metal machining. They enable precise cuts to be made in bars, tubes, profiles and other metal shapes. Their ability to cut materials as tough as steel makes them an essential tool in the metalworking industry.

- Plastics and composites: These tools are also used for cutting non-metallic materials such as reinforced plastics and other composites. They are particularly effective for materials requiring a clean, precise cut.

- Parts Manufacturing: Circular saw cutters are essential in the manufacture of mechanical parts, tooling components and other manufactured products. Their ability to make exact, repeatable cuts makes them a preferred choice for mass production.

What is a circular knife?

A circular knife is a circular-shaped cutting tool used in various industrial sectors to cut materials such as rubber, paper, cardboard, plastics, textiles, leather and even foodstuffs. In contrast to the circular saw cutter, the circular knife is designed for use with softer materials, where a clean cut is required without deforming the material.

Using circular knives :

- Paper and Cardboard Industry: Circular knives are used to cut paper sheets, paper rolls, cardboard tubes and sheets, and other packaging materials. Their sharp edges enable precise, clean cuts, essential for paper packaging and converting.

- Textile: These tools are used for cutting fabrics, garments and other textile products. They ensure clean, fray-free cuts, essential for the quality of finished products in the textile industry.

- Plastics and films: Circular knives are used for cutting plastic films, foils and adhesive tapes. Their precision prevents tears and imperfections, crucial for applications such as packaging and labeling.

- Rubber and Leather: Used in the manufacture of rubber products (gaskets, tubes, bands, plates) and leather products (shoes, belts), circular knives enable clean, precise cuts, guaranteeing the quality and durability of finished products.

- Food: In the food industry, circular knives are made of stainless steel and used to slice food products. Their use in automated food processing applications ensures uniform, hygienic slices, important for food production.