Tooth pitch and number of teeth: how to adapt the cut to the material being machined?

Publié le 18 December 2025

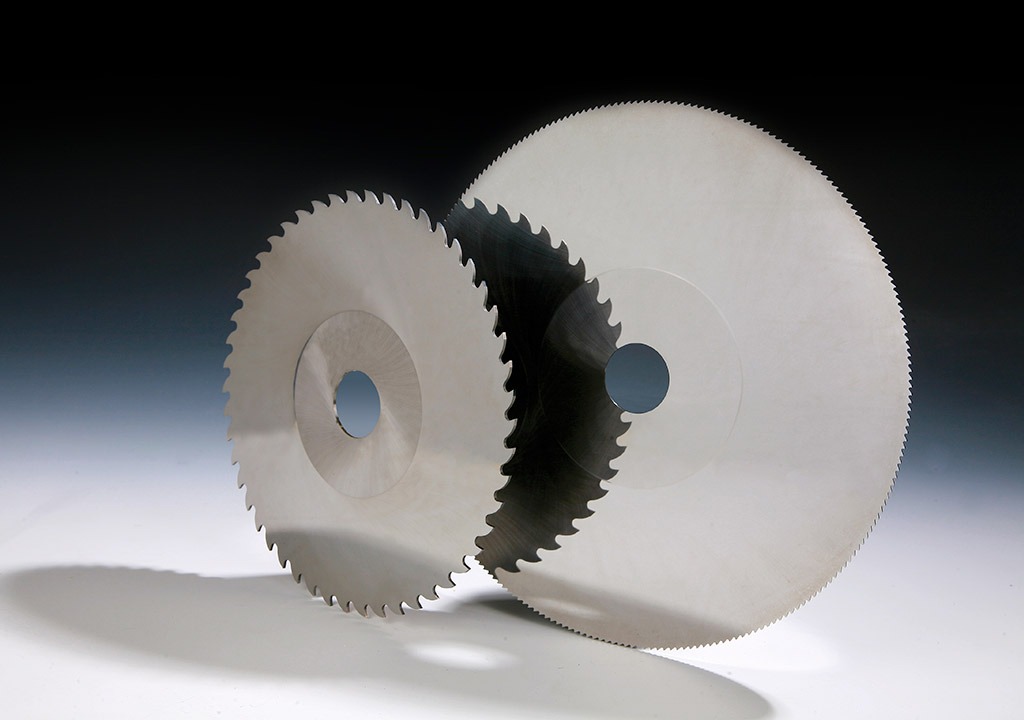

When it comes to choosing a circular saw blade, the question of the number of teeth often comes first. However, in industrial practice, this is not the decisive criterion. What really determines cutting quality, machining speed and tool life is the tooth pitch, i.e. the space between two teeth.

This parameter, which is often underestimated, must be adapted to the material being machined and its mechanical strength, as well as to the cutting conditions and the machine used.

Tooth pitch: a key parameter for cutting quality

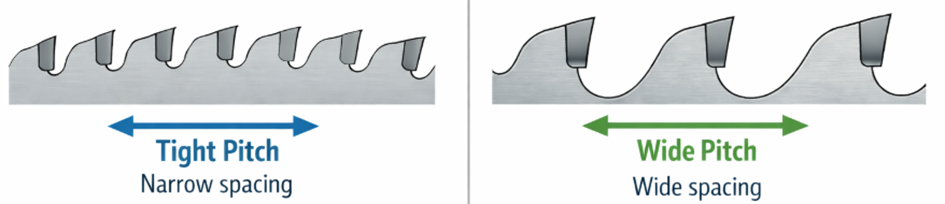

The tooth pitch is the distance between two consecutive teeth on the blade. The smaller the gap, the tighter the teeth. Conversely, a larger pitch means that the teeth are more widely spaced.

Tight toothing ensures fine, precise cutting, with good control of cutting effort. It is particularly well-suited to tough or difficult-to-machine materials. On the other hand, it limits feed speed and requires good chip evacuation.

On the other hand, a wider tooth spacing enables faster cutting. It facilitates chip evacuation but offers a less fine finish. This type of pitch is generally reserved for softer or more ductile materials.

In all cases, the tooth pitch must be considered as a balance between precision, speed and cutting stability.

Number of teeth: why this criterion alone is insufficient

The number of teeth on a blade generally varies between 20 and 200. Taken in isolation, however, this number does not allow us to judge the quality of the cut. It must be considered in relation to the blade diameter.

For example, a Ø130 mm blade with 24 teeth can offer a finish very close to that of a Ø254 mm blade with 48 teeth. In both cases, the tooth pitch is virtually equivalent. So it's not the number of teeth that makes the difference, but their distribution around the circumference.

That's why, in an industrial environment, we always think in terms of steps, not just teeth.

Match tooth pitch to material strength

The more resistant the material, the greater the need to reduce the tooth pitch to control cutting force and avoid vibration.

For mild steels, up to a strength of around 600 N/mm², an intermediate pitch generally provides a good compromise between speed and cutting quality.

When working with medium steels, between 700 and 900 N/mm², the pitch must be tightened to limit heating and premature blade wear.

In the case of hard steels, and even more so for stainless steel, Inconel or titanium, a very small tooth pitch is essential. These materials place high demands on the tool and generate considerable heat. Tighter tooth pitch ensures a more stable, more even cut, and significantly extends blade life.

| Material | Resistance | Not recommended | Effect on cutting |

|---|---|---|---|

| Mild steel | ≤ 600 N/mm² | Intermediate | Good compromise between speed and quality |

| Medium steel | 700-900 N/mm² (0.5-0.5 lb/ft²) | Tight | Reduces heat build-up and wear |

| Hard steel / stainless steel / titanium | > 900 N/mm², and | Very tight | Stable, long-lasting cutting |

| Aluminium / copper / brass | Low | Medium to large | Prevents jamming and facilitates chip evacuation |

Non-ferrous metals: attention to chip evacuation

Non-ferrous metals such as aluminum, copper and brass have a lower mechanical strength, but generate larger chips.

In this case, a too-tight pitch can quickly lead to clogging, poor chip evacuation and degraded cutting quality. A medium to wide pitch is therefore preferred to ensure smooth, even cutting, while maintaining high productivity.

Tooth pitch can never be chosen alone

In practice, the choice of tooth pitch cannot be made independently of other parameters. The cross-section to be cut, depth of cut, blade diameter, machine speed and lubrication conditions all have a direct influence on tool behavior.

This is why we systematically accompany our customers through a complete technical study. By analyzing all the constraints of the application, we are able to recommend a perfectly adapted tooth pitch and tooth type, guaranteeing performance, safety and tool life.

Conclusion

Tooth pitch is an essential lever for a successful cutting or machining operation, particularly on tough materials such as stainless steels, hard steels or specific alloys. The right choice improves finish, reduces wear and optimizes production rates.

When correctly dimensioned, tooth pitch becomes a real lever for industrial optimization, far beyond a simple choice of tooth number.