Which circular saw blade is right for cutting steel?

Publié le 18 February 2025

When it comes to cutting steel, the choice of circular saw blade is essential to ensure a clean, precise and efficient cut.

Various parameters need to be taken into account: the nature of the steel, the action to be performed, the machine used and the cutting settings. In this article, we guide you in choosing the ideal circular saw blade for your application.

Understanding the different types of steel

Steel comes in a number of categories which have a direct influence on the choice of blade:

- Mild steel (low-carbon steel): easy to cut, but prone to overheating.

- Alloy steel: contains elements such as chromium or nickel, making cutting more demanding.

- Stainless steel: highly resistant to wear and heat, requires a high-performance blade.

- Hardened steel: extremely hard, requiring a very robust blade.

- Tool steel: used to manufacture cutting tools, high strength.

- HLE (High Yield Strength) steel: designed for mechanical and structural applications, difficult to cut.

Parameters to consider when cutting steel

Before selecting a blade, several factors must be analyzed:

- Steel hardness and composition: hard steel requires a stronger blade.

- Action to be performed: cutting, grooving, precision cutting or mass machining.

- Type of machine used: manual, semi-automatic, CNC or high-speed saw.

- Cutting parameters: rotation speed, feed rate, lubrication to optimize cutting.

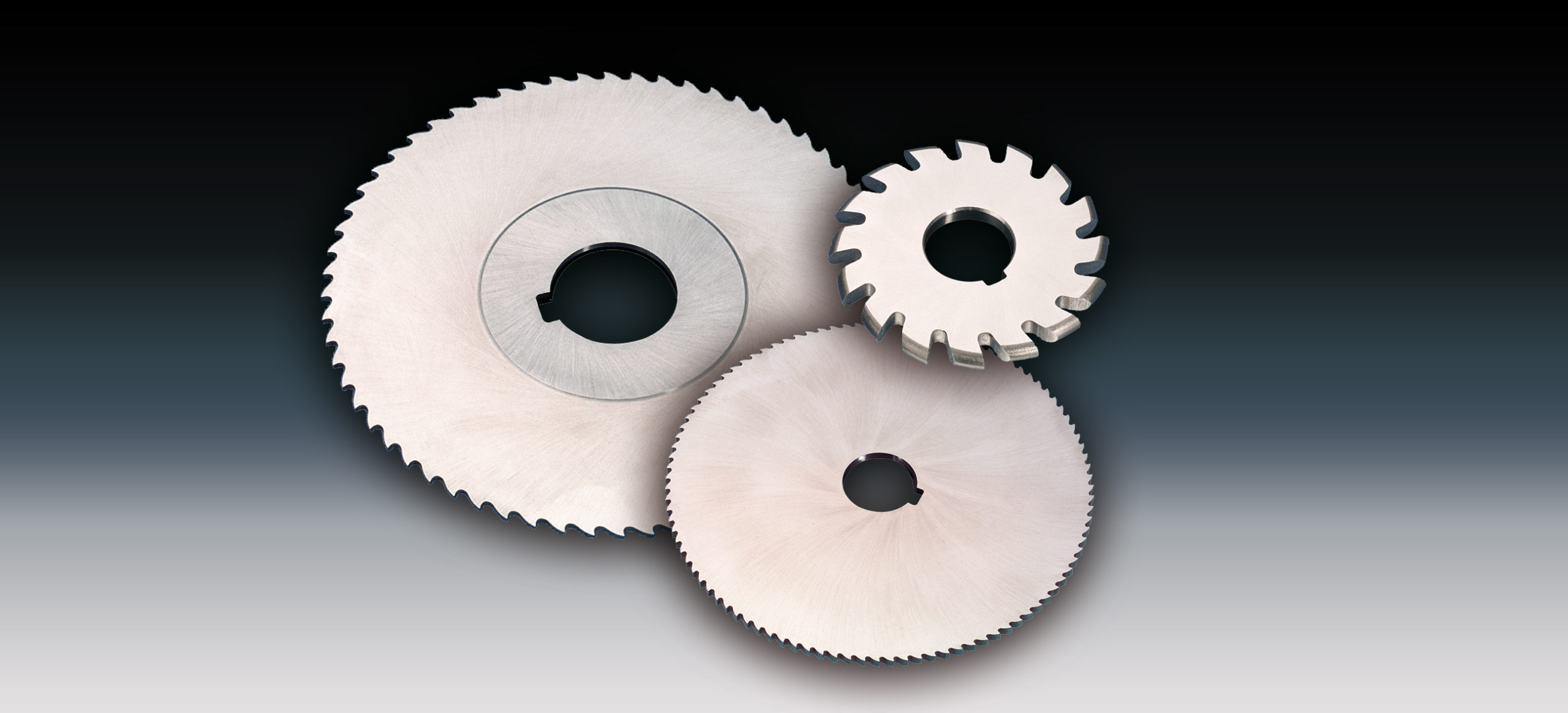

Which circular saw blades for steel cutting?

1. HSS high-speed steel blades

They provide good resistance to wear and high temperatures, and are ideal for mass production and high-speed machines.

a) HSS M2 circular saw blades

Made from M2 high-speed steel, these blades are suitable for a wide range of materials:

- Mild steels up to 600 N/mm²,

- Medium steels between 700 and 900 N/mm²,

b) HSS-E M35 (Co5) circular saw blades

Made from 5% cobalt-enriched high-speed steel (M35), they offer enhanced thermal resistance and superior durability.

Recommended for hard-to-machine steels such as :

- Stainless steel (INOX),

- Hard steels.

Ideal for orbital cutting machines thanks to their robustness and resistance to mechanical stress.

2. Solid carbide circular saw blades

- Designed for machining high-strength materials such as stainless steels.

- Enable particularly high cutting speeds.

3. Circular saw blades for cross-cutting

- Specially designed for cuttinghard steels andstainless steels.

- Resistant to wear and high temperatures.

- For greater durability and consistent cutting quality.

4. Circular saw blades with carbide inserts

a) TCT (Tungsten Carbide Tipped)

- For cuttingmedium- and high-carbon steel, as well asstainless steel

- Suitable for solid bars or thick tubes.

b) CERMET

- Ideal for cuttinglow- and medium-carbon steel.

- Designed for solid bars or thick tubes.

c) Carbide-tipped circular saw blades for non-ferrous metals (Dry-Cut)

- Suitable for dry steel cutting.

- Can be used on materials containing metal elements (nails, metal clips, etc.).

Comparison between HSS and Carbide for steel cutting

| Criteria | HSS | Carbide (TCT, CERMET) |

| Hardness of cut material | Mild to low-alloy steel | Hardened stainless steel |

| Cutting speed | Moderate | High |

| Service life | Average | Long |

| Recommended use | Fine, precise cuts | Fast, intensive cutting |

Choosing the right blade

- Analyze the nature of the steel and the desired application.

- Match blade to machine performance.

- Consider life expectancy and profitability.

- Consider regular sharpening and appropriate coating.

Don't hesitate to contact us for any customized requests or technical advice.