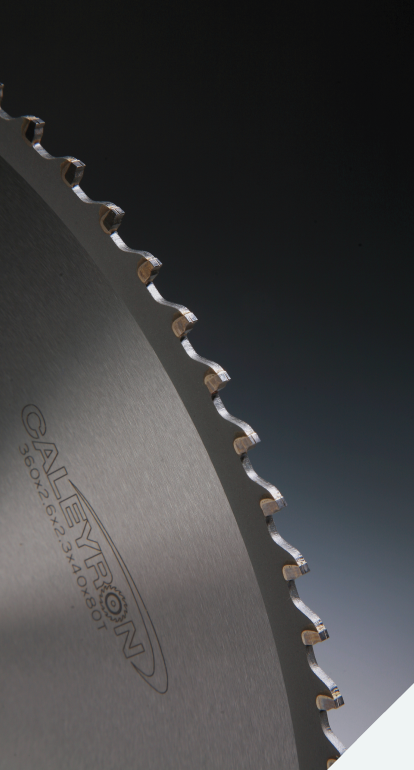

Solid carbide circular saw blades

Our carbide circular saw blades are manufactured to DIN standards, to guarantee performance. We also develop customized tools to meet your specific cutting requirements.

Our range of circular saw blades

Caleyron Industries manufactures a wide range of carbide circular saw blades, from Ø 20 to Ø 300 mm and thicknesses from 0.2 to 6 mm, specifically designed for cold cutting technology.

Solid Carbide Circular Saw Blades

Solid carbide circular saw blades are manufactured using grades K10, K20, K30, and others tailored to meet the specific needs of our clients. With diameters ranging from 15 to 300 mm, they meet the most exacting requirements thanks to extremely tight manufacturing tolerances.

These blades are specifically designed for machining highly resistant materials, such as stainless steel or titanium, enabling extremely high cutting speeds. When used on softer materials, they provide enhanced durability, significantly reducing replacement frequency.

Each saw blade is produced with an exceptional "mirror-polished" surface finish, ensuring clean and precise cuts while maintaining optimal dimensional tolerances.

The manufacturing process for these blades includes specialized production cycles that impart both exceptional hardness and high toughness. This makes them ideal for demanding applications where precision, performance, and longevity are critical.

Our coatings

Need advice on choosing the right coating for your tools?

We offer our expertise and testing resources to support you in your optimization process,

helping you select the best coating for your tools and applications.

Solid carbide circular saw blades

DIN 1837 - A

A - Fine-toothed

AW - Alternating beveled teeth

One tooth beveled to the left, one tooth beveled to the right

Shape A is used for cutting thin sections or making shallow grooves.

Shape AW helps to break up chips for better evacuation.

DIN 1838 - B

B - Coarse-toothed

BW - Alternating beveled teeth

One tooth beveled to the left, one tooth beveled to the right

Shape B is used for cutting thick sections or making deep grooves.

Shape BW helps to break up chips for better evacuation.

DIN 1838 - C

C - Alternating beveled teeth

One tooth beveled to the left, one tooth beveled to the right

Shape C is used for deep grooving, thanks to its profile, which allows for chip breaking and reduced cutting forces.

Dimensions of solid carbide circular saw blades

DIN 1837

| Thickness | 0.2 | 0.25 | 0.3 | 0.4 | 0.5 | 0.6 | 0.8 | 1 | 1.2 | 1.6 | 2 | 2.5 | 3 | 4 | 5 | 6 | |

| Diam. | Bore | Number of teeth | |||||||||||||||

| 15 | 5 | 64 | 64 | 64 | 64 | 48 | 48 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 24 | 24 | 24 |

| 20 | 5 | 80 | 64 | 64 | 64 | 48 | 48 | 48 | 40 | 40 | 40 | 32 | 32 | 32 | 24 | 24 | 24 |

| 25 | 8 | 80 | 80 | 80 | 64 | 64 | 64 | 48 | 48 | 48 | 40 | 40 | 40 | 32 | 32 | 32 | 24 |

| 30 | 8 | 100 | 100 | 80 | 80 | 80 | 64 | 64 | 64 | 48 | 48 | 48 | 40 | 40 | 40 | 32 | 32 |

| 40 | 10 | 128 | 128 | 100 | 100 | 80 | 80 | 80 | 64 | 64 | 64 | 48 | 48 | 48 | 40 | 40 | 40 |

| 50 | 13 | 128 | 128 | 128 | 100 | 100 | 100 | 80 | 80 | 80 | 64 | 64 | 64 | 48 | 48 | 48 | 40 |

| 63 | 16 | 160 | 128 | 128 | 128 | 100 | 100 | 100 | 80 | 80 | 80 | 64 | 64 | 64 | 48 | 48 | |

| 80 | 22 | 160 | 160 | 128 | 128 | 128 | 100 | 100 | 100 | 80 | 80 | 80 | 64 | 64 | 64 | ||

| 100 | 22 | 160 | 160 | 128 | 128 | 128 | 100 | 100 | 100 | 80 | 80 | 80 | 64 | ||||

| 125 | 22 | 160 | 160 | 128 | 128 | 128 | 100 | 100 | 100 | 80 | 80 | ||||||

| 150 | 32 | 150 | 150 | 150 | 128 | 128 | 128 | 128 | |||||||||

| 160 | 32 | 160 | 160 | 160 | 128 | 128 | 128 | 128 | |||||||||

| 200 | 32 | 160 | 160 | 160 | 128 | 128 | |||||||||||

DIN 1838

| Thickness | 0.2 | 0.25 | 0.3 | 0.4 | 0.5 | 0.6 | 0.8 | 1 | 1.2 | 1.6 | 2 | 2.5 | 3 | 4 | 5 | 6 | |

| Diam. | Bore | Number of teeth | |||||||||||||||

| 15 | 5 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| 20 | 5 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| 25 | 8 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| 30 | 8 | 30 | 30 | 30 | 30 | 30 | 30 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 |

| 40 | 10 | 40 | 40 | 40 | 40 | 40 | 40 | 32 | 32 | 32 | 32 | 24 | 24 | 24 | 20 | 20 | 20 |

| 50 | 13 | 48 | 48 | 48 | 40 | 40 | 40 | 32 | 32 | 32 | 24 | 24 | 24 | 20 | |||

| 63 | 16 | 64 | 64 | 64 | 48 | 48 | 40 | 40 | 40 | 32 | 32 | 32 | 24 | 24 | |||

| 80 | 22 | 64 | 64 | 64 | 48 | 48 | 48 | 40 | 40 | 40 | 32 | 32 | 32 | ||||

| 100 | 22 | 80 | 80 | 64 | 64 | 64 | 48 | 48 | 48 | 40 | 40 | 40 | 32 | ||||

| 125 | 22 | 80 | 80 | 80 | 64 | 64 | 64 | 48 | 48 | 48 | 40 | 40 | |||||

| 150 | 32 | 80 | 80 | 80 | 64 | 64 | 64 | 64 | |||||||||

| 160 | 32 | 80 | 80 | 80 | 64 | 64 | 64 | 64 | |||||||||

| 200 | 32 | 80 | 80 | 80 | 64 | 64 | |||||||||||

Need a made-to-measure blade?

Depending on your requirements, we can produce a toothing with customised dimensions (non-standard)